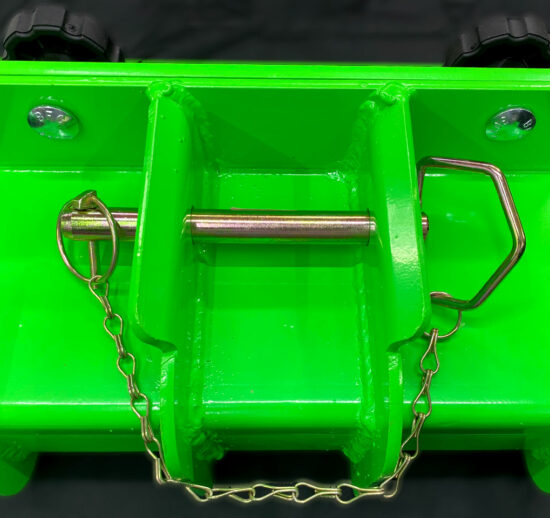

Shed Stabilizer

$460.00

Adjustable, aluminum and powder coated stabilizer bar for mini barns. This will keep your shed wall stiffer when moving it.

Ships in 2 boxes.

Mini Barns have become a popular business. Built off site and moved to the customers land, they are built tough, but have some moving issues that should be looked at. While being loaded onto the trailer, the twisting and racking starts. How many miles do they travel and over what roads- good or bad, hilly or flat, pot holes or chatter bumps? When they get to the delivery site, how is the terrain, flat, sloped, and what is the location they are to be placed in or on. Much care is used in driving and with the Mule, but there are stress points on every building. Too much pressure or a bit of extra push and the paint seal can crack, the wall can be pushed in- just a little, but a bigger weak spot is there, worse thing can and have happened. The Shed Stabilizer stiffens the walls so the pushing and shoving damage is lessened. The adjustable head fits around a stud, under and against the top plate. The extra wide foot plate is lagged to the floor and has various holes to make it longer or shorter as needed. The lite weight aluminum pole has a ratchet system on it making it easier to snug the final inches.

Use the Stabilizer and save a shed!